The Product Circularity Data Sheet (PCDS) is a basic source of verifiable data. It can be used to establish how circular a product is and inform about the circular path it was designed and manufactured for. The PCDS offers a standardized format with trustful data without scoring or ranking of these aspects.

The PCDS is a three-fold system:

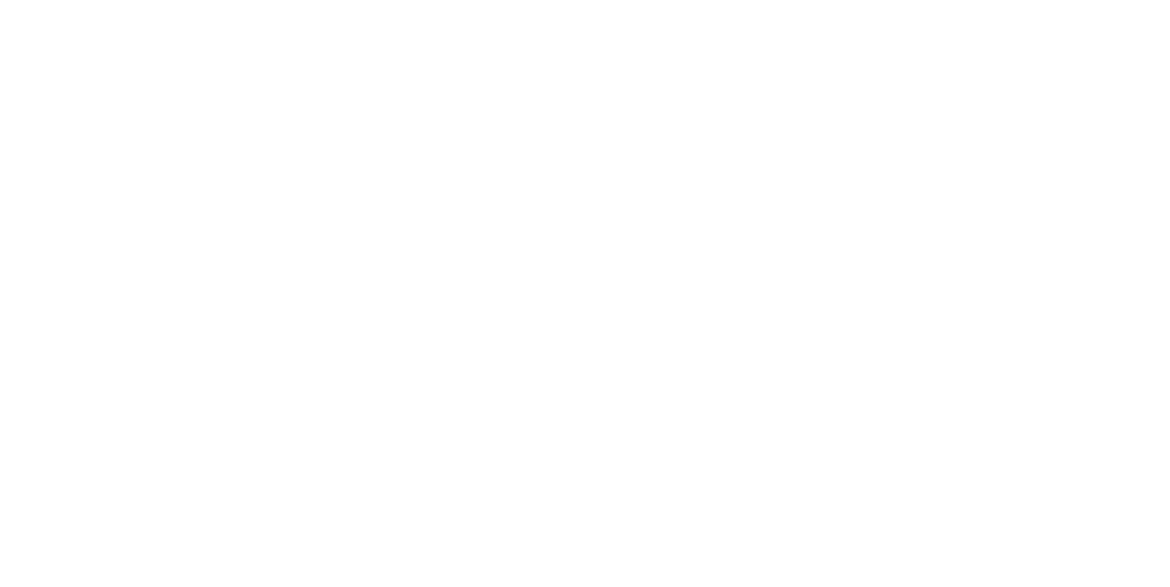

- A data template containing standardized and trustworthy statements on the product circularity

- A third-party verification process to validate the content of the PCDS (audit system)

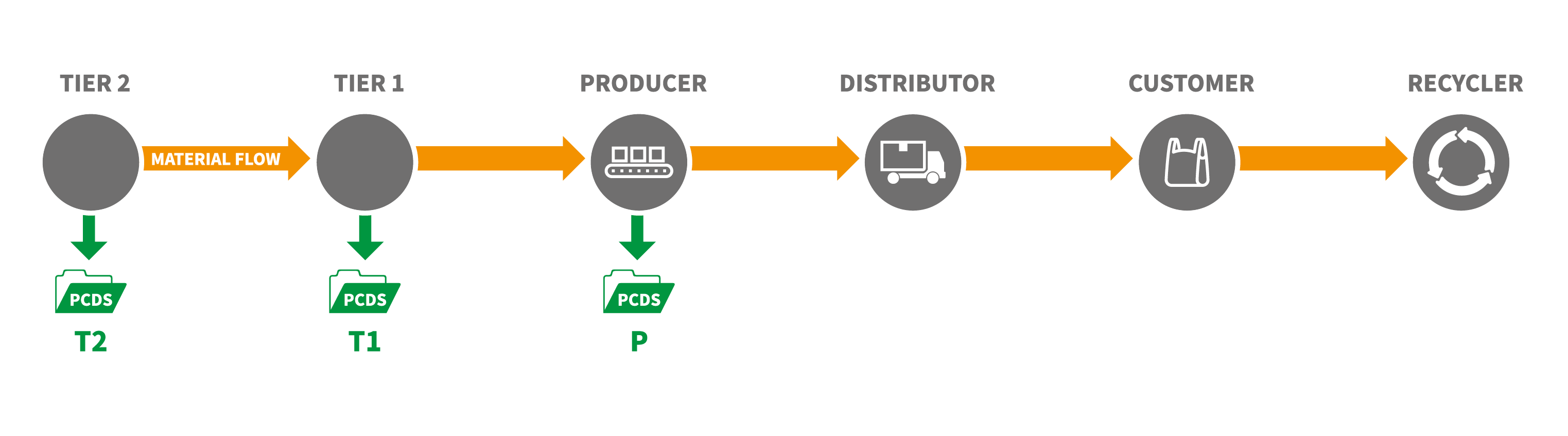

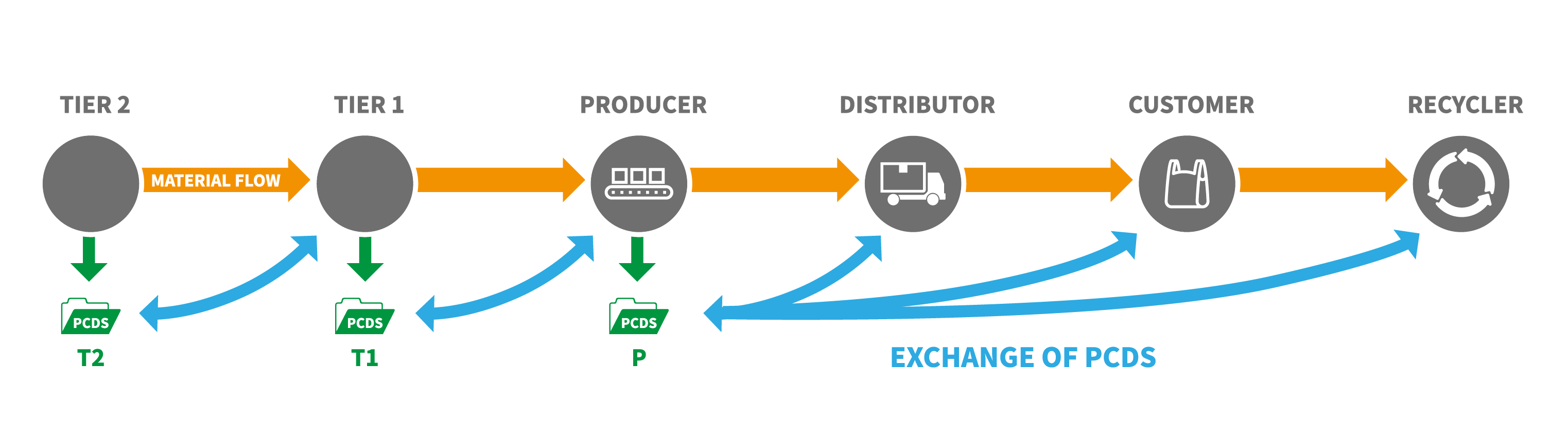

- A standardized data exchange protocol based on decentralized data storage (IT system)

It has 3 objectives:

- Provide basic data on a product’s circularity to all relevant stakeholders

- Improve the sharing efficiency of circularity data across supply chains

- Encourage the improvement of product performance in terms of circularity

The general structure of the PCDS system is inspired by the MSDS system (Material Safety Data Sheet) that provides standardized statements to describe the safe use of chemical products/mixtures.